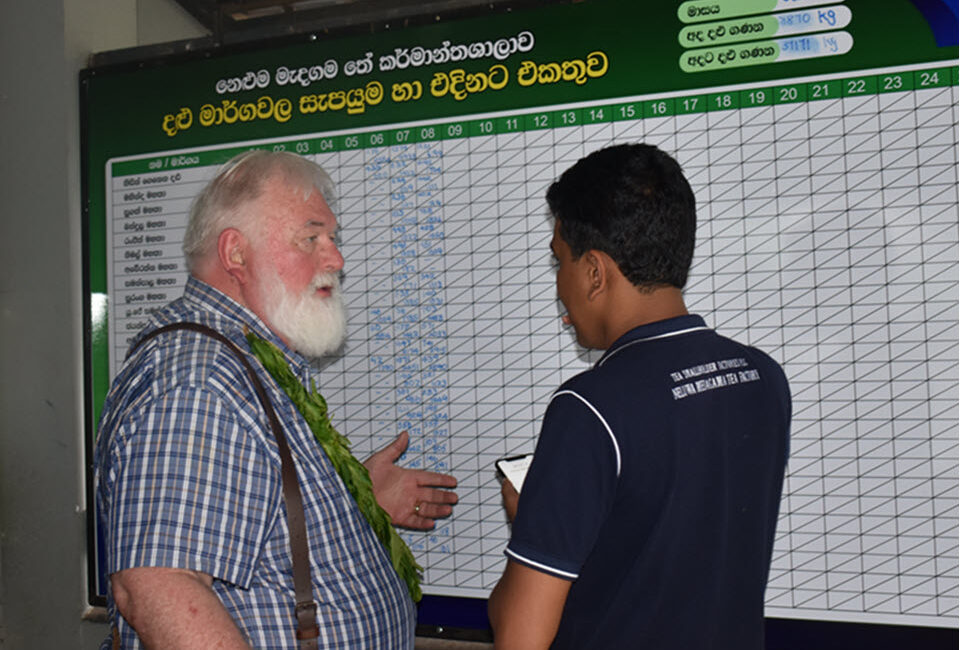

Romesh Walpola, Chief Executive Officer of Tea Smallholder Factories, Ltd. (TSFL) in Sri Lanka, explains how the Colombo-based firm taps the output of one to 10-acre farms to produce approximately three million kilos of tea annually. Investing in smallholder training, wellness, and educational programs, including internships for second-generation farmers, earns the loyalty of thousands of small tea growers and top dollar for teas sold at auction.

- Caption: One way that Tea Smallholders Factories, a division of John Keells Group, invests in smallholders is by hosting events, including free health checkups pictured above, at which healthcare providers prescribe medicine to 1,021 factory employees and nearby community members supporting the Neluwa Tea Factory.

Tea Smallholder Factories Earn Loyalty that Maintains Competitive Quality Teas

By Dan Bolton

In aggregate, farms of 10 acres or less contribute 77% of Sri Lanka’s total tea crop, according to Plantations Minister Ramesh Pathirana. That percentage has increased over time. Bought leaf factories purchase an estimated 70% of the tea grown by smallholders.

Large estates own 56% of the 202,985 hectares under tea, according to the Sri Lanka Tea Board’s annual report, but contribute only a quarter of the 250 to 300 million kilos of tea processed annually. Sri Lankan smallholders cultivate about 44% of the land under tea, selling to large estates and bought-leaf factories. Only 18% of Sri Lanka’s factories process tea exclusively grown on their estate.

All sectors compete at the weekly Colombo Tea Auction, under the aegis of the Ceylon Chamber of Commerce. Around 6.5 million kilos of tea are sold weekly at this global marketplace where quality is rewarded with the world’s highest average auction prices for black tea.

Tea Smallholders Factories, Ltd. is an example of a successful public-private partnership, explains CEO Romesh Walpola. The company, which employs 411 workers, processes green leaf procured from 8,698 tea smallholders and green leaf collectors. In the fiscal year ending March 31, 2023, TSFL reported an 85% increase in revenue totaling LKRs. 3.74 billion compared to 2021-22 and a profit before taxes of Rs. 440 million (growth of 1,845% YOY with a dividend per share of Rs. 6.67). TSFL accomplished these strong results during a year in which Sri Lanka’s total gross domestic product (GDP) contracted by 7.8%.

Tea Smallholder Factories Output

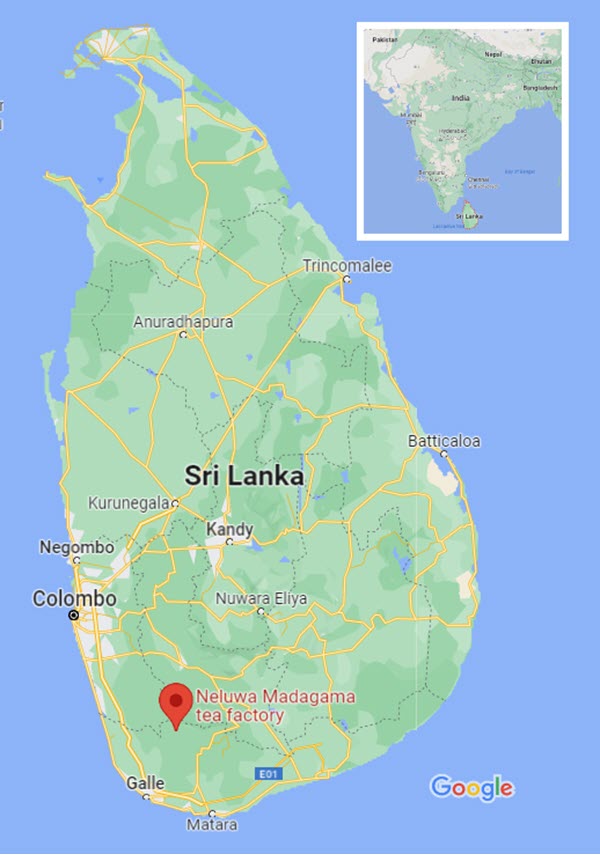

Neluwa Tea Factory: annual production 883,000 kgs | 1,413 suppliers

Halwitigala Tea Factory: annual production 888,000 kgs | 956 suppliers

Hingalgoda Tea Factory: annual production 1,075,000 kgs. | 892 suppliers

Kurupanawa Tea Factory: annual production 888,000 kgs | 925 suppliers

New Panawenna Tea Factory: annual production 1,115,000 kgs | 1,473 suppliers

Broadlands Tea Factory: annual production 952,000 kgs. | 3,100 suppliers

Link to 2022 Annual Report | 2023 Annual Report

Dan Bolton: Romesh, how competitive are bought-leaf factories in a premium black tea market like Sri Lanka?

Romesh Walpola: We compete heads-up with some of the key private factories. Competition is fierce, as you would know. We are located mainly in Galle and Ratnapura and have one factory in Ginigathhena. The competition is in Galle, and Ratnapura is quite tenacious and very competitive. Most are private factories owned and operated by listed companies.

Dan: The Sri Lanka Tea Board estimates growers earn about $6,000 (LKRs 2 million) per hectare annually. Yields average 4,000 to 5,000 kilograms per hectare. Input costs vary, and labor expenses are far lower for smallholders. Will you describe the typical smallholders that sell your factories green leaf?

Romesh: On average, they own about an acre or less outright.

Dan: May I summarize the basics? Tea is grown as a cash crop mainly for export. Plantations and smallholders alike plant at a density of 5,000 to 6,000 bushes per acre. Smallholders manage a mixed use property acquiring and apply fertilizer and inputs for tea as well as home-grown food. Smallholders often involve their children and extended families in farming to lower labor expenses.

Do the thousands of growers you work with produce tea in disciplined rounds? Or do they pluck on occasions when they’re not doing something else?

Romesh: Yeah, they maintain between seven to 10 days of plucking rounds.

Dan: Are they third-party certified? Organic?

Romesh: Not really, not organic. There are a few smallholders who own organic acres as well. But very few.

Dan: You explained that training and quality control are a big part of your contribution to their success.

Romesh: Yes. We have our extension officers in the field on a daily basis. And they have little pocket groups that are educated on basic soil management, the type of fertilizer to apply, pruning cycles, and recommended plucking rounds, all that is needed to maintain their plots. We give that service to the smallholders, but apart from that, they do their own thing as well.

Dan: It sounds like you are empowering these growers to become rural entrepreneurs, right? They control their fate. As growers, they maintain leaf quality. They must deliver a high percentage of fine-plucked leaves from each round.

Romesh: That is one area that we are very particular. I mean, we don’t take just any leaf. We are very selective. We encourage them to bring a decent standard because, as you know, if you put some garbage in, you get garbage out, right, so you have to make sure your raw material is good for you to have an end product so we’re very picky in terms of you know, selecting a reasonably good standard of leaf.

Dan: Do you incentivize quality.

Romesh: Yes. We give them a small incentive for what we call super leaf. Let’s say the current standard of fine leaf pluck (two leaves and a bud) is at about 50 to 55% of what they pluck when you get something over 60 to 65%; then, we give them an incentive for that amount of leaf they bring.

So that it’s, you know, encouraging them to raise the bar for themselves and get something back in turn. We teach them that the higher the tea price at the auctions, the higher the green leaf payment according to the tea board’s formula. So that’s the positive of this vicious cycle, we keep telling them.

Dan: Have you established a minimum rate for green leaf, a price floor?

Romesh: Most of the time, but there are instances we are not during the rush period. We look at what the competition is doing when there are lean months. And we try not to overpay because we don’t believe in, you know, just because the neighbor pays X, you go and try to match that? Because it has to make sense financially.

Dan: It’s a business.

Romesh: Exactly.

Dan: And the nature of the business is that your costs fluctuate, as does the price at auction.

Romesh: In the long run, if you go down that path of paying a rate based on what the neighbor is paying, it doesn’t make real business sense.

What we do is add a lot of value to their livelihoods.

Key Performance Indicators (2023 Annual Report)

| 2023 | 2022 | 2021 | |

| Tea production in kilos | 2,463,000 | 2,966,000 | 3,631,000 |

| Net sale average USD | Rs./kg | $4.82 | 1,554.58 | $2.03 | 653.67 | $2.06 | 664.54 |

| Revenue from Customers (USD) | $11,614,000 | $6,262,000 | $7,278,000 |

| Profit after Tax (PAT) (USD) | $864,000 | $47,500 | $206,400 |

Loyal Smallholders

Romesh: We’ve identified that group of loyal smallholders who don’t go to any competition if they offer a few more rupees.

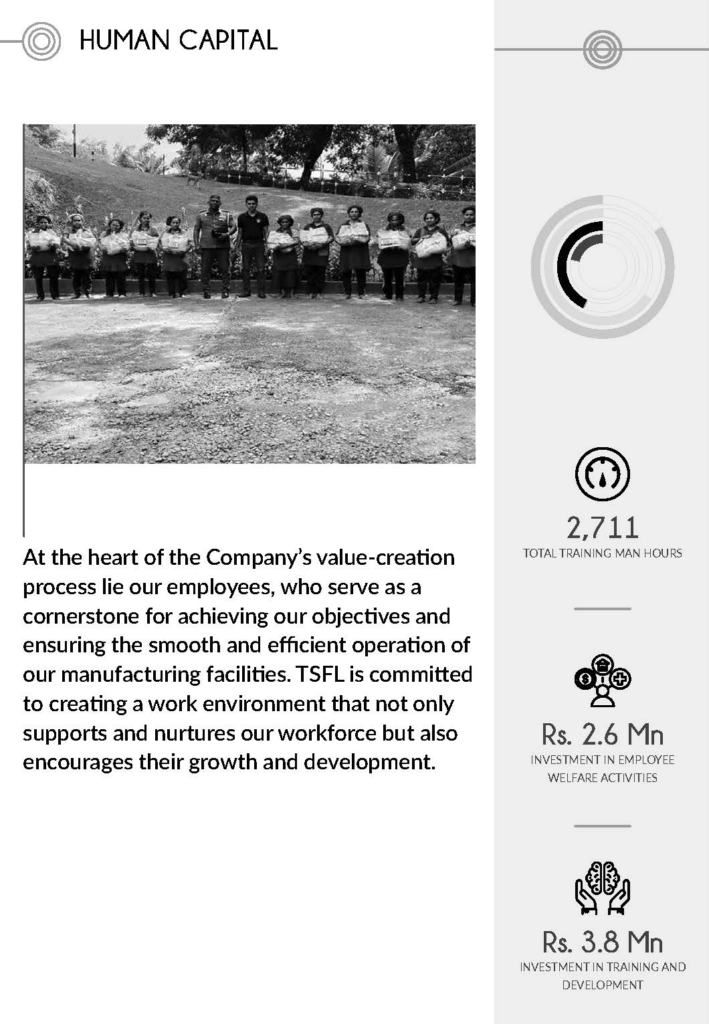

I will give you some examples of what we are doing for them. Last year we completed 20 projects and initiatives to positively impact the communities surrounding our business operations.

Just a month ago, we arranged the region’s largest health camp on our premises, so we had roughly 1,000 plus villagers and smallholders coming in to get their health checks. And that was a huge deal for them because some of them had never even had a simple blood sugar test so you could detect problems. Then this is what we do for the community.

They are concerned about the next generation in tea, their children.

There are scholarship programs that we are conducting for the schoolchildren in the vicinity, and for the next generation of smallholders, we offer internships to study the whole factory process and learn about manufacturing. Plus, we explain what happens after the dispatch so that they understand the sampling and laboratory testing that happens between the broker and buyer. Then we take them to a buyer and give them that full experience and exposure. And after completing that cycle, we will find them employment within the industry. They could eventually become a buyer or brokers — even own their own factories. So that’s the educational part that we’re doing.

We do this on a regular basis training 11 interns last year. And once they finish, we give them a certificate. Young people leave our farms otherwise.

Smallholder Profile

Smallholder Mrs. Chandra Jayasingha, 62, farms an acre of tea on land where she and her husband also grow several cash crops, including spices, pepper, coconut, and bananas. The approximately 5,000 tea plants (Cultivar D2026) are not certified organic but are cultivated using organic practices.

“The significance of social and relationship capital as a valuable

– TSFL 2023 Annual Report

asset for creating value will continue into the future, playing a

crucial role in driving the sustainable growth and performance. Accordingly TSFL’s primary focus will be on sustaining our green leaf suppliers, especially small holder partners by providing value-added services to support sustainable agricultural practices and environmentally friendly approaches.”

Dan: Sri Lanka’s tea industry, led by the tea board, plantation owners, and growers’ associations, have signaled their intent to make tea production sustainable.

Romesh: Sustainability is something that we are also looking at. Smallholders are fully aware of, you know, its importance. Sustainable practices at the factories and by the company contribute to stickiness amongst loyal smallholders.

So for us, it’s not about paying something a little bit more than the competition when taking leaf; it’s about actually deep diving into, you know, looking at enhancing the livelihood of the community and the smallholders.

Smallholder Profile

Dayananda Matarage, 67, owns the 10-acre Gulanahena Estate in Thiniyawala in the foothills of the Sinharaja Rainforest. The son of a planter, he produces 3,000 kilos of green leaves on six acres planted in TRI 2022-27 and 4042-49 cultivars. He first planted tea on 1.5 acres in 2001, expanding gradually, recently adding two acres. The main fertilizer is an organic compost, to which he adds bioliquids to enhance micronutrients. He does not use plant protection chemicals or herbicides. He hires local field workers part-time to pluck tea and harvest coconut, pepper, pineapple, sopa, rubber, papaya, and bananas, and he offers a homestay through Sinharaja Holiday Bungalows. Tea generates 75% of the farm’s revenue. A retired engineer, he makes a delicious homemade kombucha he shared with us in his kitchen with rice and coconut milk welithalapa and oil cakes.

“The COVID-19 pandemic and the worst economic crisis in Sri Lanka’s post-independence history resulted in an increase in poverty rates of up to 25% in 2022, a dramatic increase from 11.3% in 2019. Although one fourth of the country’s population has fallen into poverty, many do not receive monetary support from the government, largely due to the weaknesses of social welfare schemes. More than 50% of Sri Lanka’s poorest population is not covered by the government welfare programs”

– The World Bank

- The International Labour Organization describes Sri Lanka smallholders as farming 10 acres (four hectares) or less. As defined in the Tea Control Act, Small Tea Holdings produced approximately 95% of the low-country tea, 59% of the middle-country tea, and 15% of Sri Lanka’s up-country tea in 2014.

Related:

Visit Neluwa, Sri Lanka (Wikipedia)

John Keells Plantations Services

John Keells Holdings

- Dan traveled more than 1,500 kilometers during a 10–day visit to Sri Lanka in May 2023. My travels were sponsored by the Sri Lanka Tea Board, chaired by Naraj de Mel, with accommodations at the Tea Research Institute courtesy of Dr. K.M. Mohotti. “I’m deeply grateful for the joyful days spent with Pavithri Peiris, the tea board’s Director of Promotion, Gayan Samaraweera, Market Promotion Officer, and Chathura Fernando, Market Analyst. Gayan and Chathura photographed the scenes above.

Link to share this post with your colleagues

Signup to receive Tea Biz weekly newsletter in your inbox.