A sustainable future in tea depends on a shared responsibility among stakeholders to assure living wages (for workers) and a living income for smallholders. Last fall IDH, the Sustainable Trade Initiative, introduced the Living Income Roadmap, an extension of the Roadmap on Living Wages, launched in 2019. These online platforms provide companies and brands with the resources they need to understand the gap between a living wage and what workers earn. The platform’s wage matrix helps identify gaps and guide businesses to develop strategies to make continuous progress in closing the gap. Case studies show that companies that pay a living wage achieve greater productivity, less turnover, and a competitive marketing advantage by improving the wages and ultimately the quality of life for workers.

- Caption: Judith Fraats, senior program manager at IDH in Amsterdam

Hear the interview

Achieving Living Wages is a Shared Responsibility

By Dan Bolton

A living wage is the calculated wage needed for a basic but decent standard of living. Minimum wages are just that, a floor below which wages cannot fall. A living wage provides workers enough income to cover housing and groceries, healthcare, education and transportation, with a cushion for the unexpected.

The IDH Roadmap on Living Wages helps workers secure living wages in supply chains globally. Achieving living wages is a shared responsibility across the entire supply chain. The program encourages stakeholders to align to strengthen their resolve. Case studies demonstrate that closing living-wage gaps is achievable without price escalation when best practices are employed. IDH has discovered that transparency and sustainable practices, beginning at the farm and extending to every link in the supply chain, adds value that is rewarded by consumers.

Dan Bolton: Why is achieving a living wage for tea workers at origin a priority?

Judith Fraats: Inequality is a big trend that we’re facing globally at the moment. Moving towards living wages enables structural change to break the cycle of poverty. But it also helps us to move towards a more inclusive society and reduce some of these inequalities.

Let’s not forget that an adequate standard of living is a fundamental human right.

Second, we see a growing amount of consumers, mostly in developed countries, that are asking these questions of their retailers and the brands that they consume: Can you prove to us that the workers and the farmers who have been engaged in making this product that they are able to earn a decent living?

Do they earn enough with what you’re paying them?

Dan: In tea, labor issues and wages attract consumer scrutiny and debate. Will your share IDH’s experience in the tea sector?

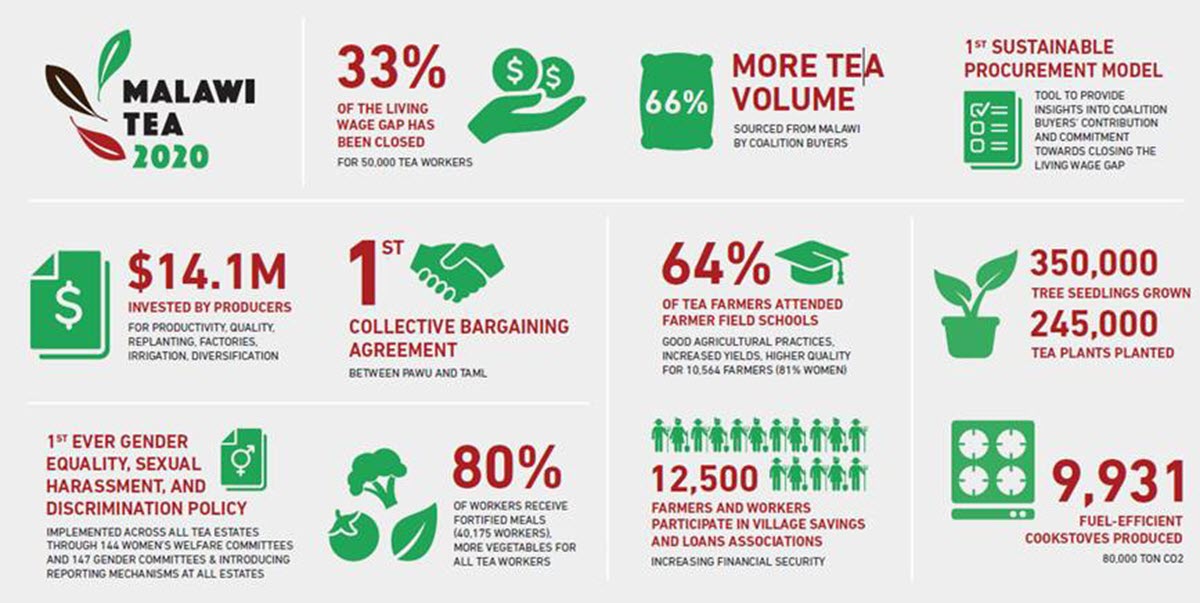

Judith: I think some of the listeners are familiar with the program that we’ve run on living wages in Malawi called Malawi Tea 2020 a supply chain-wide commitment on living wages.

The objective was to ensure that the Malawian tea industry remained competitive while working towards a living wage for its workers and living income for smallholders.

The predominant focus of this program was on living wages. That program had a wide set of partners — we convened 36 organizations with living wage at its core but also looking at holistically a number of other areas which needed to be incorporated in order to address living wages.

One of the things at the center of this, is that we can’t work on wages if there is no tea industry in the future in Malawi, right? The 9,000 smallholders enrolled in the Farmer Field Schools (FFS) led to a yield increase of nearly 22% the first year and of 41% in the season after graduating. FFS farmers also had a higher percentage of green leaf rated as ‘good’ (73%) compared to non-FFS farmers (56%) in the year after graduation.

Competitiveness is a really important aspect, looking at how can we enhance productivity and quality, but also looking at how can we further improve social dialogue. One of the things that we managed to achieve was the development of the first collective bargaining agreement, for example.

Over a five-year period, we’ve been able to reduce the living wage gap, from two-thirds to one-third. Which means that there is still a gap, but we’ve come quite a long way. As IDH, we’re here to continue working with the tea industry to help them on their journey in living wages, and to make progress to close living wage gaps together.

Dan: Will you explain the difference between a living wage and a living income?

Judith: The term “living income” is coming up more and more because when we talk about smallholders, we are actually not talking about a living wage. That’s when we start talking about living income. The concept is similar. Both focus on achieving a decent standard of living for households. However, living wages applies to a hired worker setting, whilst living income focuses on a self-employed farmer, for example.

Dan: IDH introduced “The Roadmap on Living Wages” to help companies secure living wages along the entire length of their supply chain. Will you explain the roadmap to listeners?

Judith: The roadmap has been built on best practices that we’ve gained throughout the years working not only within the tea sector, but also flowers, apparel, and fruit and vegetables, for example.

It consists of five steps. The first is to identify what is the living wage benchmark for the region that you’re sourcing from. We have a benchmark tool available on the IDH website where you’re able to identify which benchmarks are available for your sourcing regions. Once you know the benchmark, you obviously would like to know whether there is a difference between the actual wages that are being paid by the suppliers within your supply chain.

To help companies in that process, we have developed the Salary Matrix, which is a self-assessment tool for producers to calculate current remuneration including wages, bonuses, cash, and in-kind benefits. This is then compared against the living wage benchmark. The tool helps you to understand the size of the gap, if there’s a gap at all. It also helps you monitor progress over the years and support work with, for example, certification programs that are continuously improving their living wage requirements.

In step three we recommend you find a trustworthy way of verifying those calculations as a principle of self-assessment. One of our goals at IDH is that these gaps are verified by audits through certification schemes. We are not there yet completely. But it’s a process that’s very much ongoing.

“IDH is committed to taking action and working together to have as a minimum a living wage for everyone in the workplace. We encourage more companies to get started. IDH is ready, we have the roadmap and are keen to support you in your living wage journey.”

– Judith Fraats

I think the most tricky step is actually closing the gap. Once the size of the gap is clear, you need creative and innovative approaches to remove these barriers to make progress towards closing this gap, which we believe is a shared responsibility and should be done in close connection with local stakeholders.

The fifth step is sector-specific, and also context-dependent but you can learn so much across from all these different experiences, by sharing insights, learnings, best practices, what has worked well, what hasn’t. This is really key to further advance the living wage journey

Those are the five steps of the roadmap in a nutshell. Last fall we developed the Living Income Roadmap, which mirrors those five steps. They’re the same, although the actual process and implementation are obviously tailored to the smallholder setting.

Dan: What’s the bottom-line benefit to brands and tea companies and how do they sign up?

Judith: We hope that the roadmap provides guidance to companies that want to make progress towards closing the living wage gaps, and also helps to bring alignment within the more academic world on living wages. We’ve built this roadmap to help companies make progress. It is based on best practices with input from the private sector, but also civil society, other NGOs and sustainability and expert organizations. Together they really brought this roadmap to its fruition.

Related

- The Big Picture: Improving Wages by Amanda Penn

- Preferred by Nature (Third-Party Verification Services)

- Different Paths, Common Goal: How More Companies Are Providing Living Wages

- Call to Action: Better Business through Better Wages

Link to share this post with your colleagues

Signup and receive Tea Biz weekly in your inbox.