In a dynamic beverage market crowded with healthy options, tea can’t afford to sit back and rest on its leafy laurels. Continuous consumer-focused innovation is essential from soil to cup.

Much has been spent on earth-friendly packaging and third-party certifications to differentiate offerings on the shelf — but the tea within is largely unchanged. Innovations in tea processing are too few.

New technologies and business models, such as blockchain-based traceability, e-commerce platforms, and direct-to-consumer channels, enhance transparency, efficiency, and consumer engagement but do not necessarily result in better-tasting tea.

Market research reveals that tea drinkers prefer the leafy appearance and aroma of whole and broken-leaf teas but insist on the convenience of sachets and a colorful, robust, quick brew. Inspired by this unmet need, Narendranath Dharmaraj, a 40-year tea industry veteran in Kerala, India, has developed an economical technique that rids tea of stringy fiber skeleton resulting in a substrate superior to fannings and dust.

Extruded tea is a malleable hybrid format that retains the fragrance of well-made, orthodox tea. The adaptable substrate can be blended to improve conventional CTC or pressed and die-cut to resemble broken-leaf grades. Imagine 3D-printed tea in myriad shapes and sold at a premium.

Listen to the Interview

Tea manufacturing has a rich history and 150-year tradition, but must embrace a new approach to stay relevant and competitive. Since the 1960s innovation has been limited to the development of machines that deliver economic efficiency, packaging, convenient formats, and flavors. It is time to explore new processing techniques, such as fermented semi-orthodox teas, as well as new ingredients, blends, and functional properties to meet the evolving demands of consumers. A makeover of the product paradigm is imperative. It’s time to give camellia sinensis a new lease of life to boost consumer appeal for tea.

Tea Manufacture: Futuristic Development Opportunities

By Narendranath Dharmaraj

Not much has changed in tea manufacturing in this traditional and tradition-bound industry. Orthodox, as it literally means, is the original production method of tea with a typically twisted leaf appearance and liquor characteristics delivering flavor and aroma. Such teas are best brewed by steeping in boiled water for a few minutes and typically yield fewer cups per unit weight of tea described as ‘cuppage.’ Normally the withering is hard, meaning more moisture is removed from the leaf, and the withered leaf is subjected to gentle and limited maceration in gently rotating rollers to express just enough juice to impart the aroma and flavor over longer periods of ‘fermentation.’ The target is to maximize the whole leaf and rolled nutty leaf grades which typically result from a combination of finer green leaf quality and careful adherence to manufacturing parameters (many of the ‘specialty teas’ are in these grades).

Methodologies: Orthodox

Orthodox (ODX) describes the original production method of tea. Processing typically results in a twisted leaf appearance with liquor characteristics that deliver superior flavor and aroma. Orthodox teas are best brewed by steeping in boiled water for a few minutes. The method yields fewer cups per unit weight of tea or ‘cuppage.’ Withering is hard, meaning more moisture is removed from the leaf, and the withered leaf is subjected to gentle and limited maceration in gently rotating rollers. This is to ensure the leaves express just enough juice to impart the aroma and flavor essential during longer periods of ‘ fermentation’. The target is to maximize the whole leaf and rolled nutty leaf grades (many of the ‘specialty teas ‘ belong to these grade brackets) which typically results from a combination of finer green leaf quality and careful adherence to manufacturing parameters.

Rotorvane Orthodox

Rotorvane orthodox involves passing the rolled leaf through a screw-type machine called ‘Rotorvane’ that uniformly breaks the leaves which are sized down for higher ‘cuppage’ than ODX, yet retaining flavor and aroma, typically targeting higher recovery of BOP (broken orange pekoe) and BOPF (broken orange pekoe fine) grades.

Cut, Tear, and Curl

CTC emerged as the preferred system of manufacture as cuppage and faster infusion (tea bags) became a consumer requirement. As indeed a way of utilizing the less fine leaf that resulted from the drive to increase crop volumes to keep the ever-increasing cost of production under control. The withering was softer (less moisture was removed), and the maceration, which included a shredder, rotorvane, and sharpened and reciprocating rollers working at high RPMs, was more severe. Fermentation takes less time and the resultant tea is granular, somewhat flatter and dusty with strong, coloury, and fast-infusing liquor. The targeted grade was BOP, PD, PF, and Fine Dust for specific markets.

In geographies where driving costs with higher crops and specific brewing methods demanded a tea that could stand repeated brewing (high cuppage), the CTC metamorphosized into reconditioned teas which meant recycling some of the inferior grades back into the maceration process. The focus here was to maximize the Dust grades that these markets demanded.

Green and Oolong Tea

Green tea can either be CTC or orthodox, although typically, the preferred grades are gunpowder and Chunmee, resembling the orthodox teas. Green tea manufacturer instantly remove moisture in green leaves through ‘Panning’ (Chinese method) or ‘steaming’ (the Japanese Sencha). Oolong is semi-fermented tea – more akin to green than black tea.

Grade Classification

In CTC and Orthodox manufacture, there are four universal classifications: leaf, broken leaf, fannings, and dust. Typically the first two are a ‘brewer’s cup,’ and the last two are of the tea bag variety, although some of the leafy teas also are now finding their way into a tea bag. Multiple grades have been introduced by buyers based on their trade requirement, making life difficult for the producer and not without some harm to ‘quality’ that results from over sorting. I, for one, have campaigned for zeroing in on improvements to the four grades.

Need for Objective Quality Assessment

In evaluating the quality attributes in tea, the reckoning parameters are leaf appearance (blackness, density, fiber-free, uniform size); spent leaf, denoting evenness of size, and infusion primarily ‘brightness‘ of liquor, a description that includes the color, flavor, aroma, taste (astringent without leaving a bitter aftertaste) as well as weight to volume ratio or density “cuppage” as is popularly called along with moisture content, a guide to storage and staling qualities.

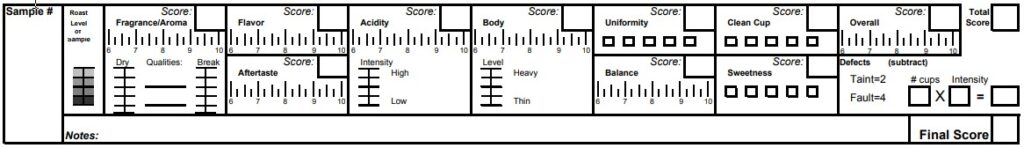

Tea tasters are adept at deciphering these quality attributes, bringing value to the quality assessment process. However, the downside of this assessment system is its inability to numerically quantify measurements. I worked on getting all the above quality attributes under an iterated scoring system of 1 to 10, each of which score is well defined.

See: Protocols & Best Practices for Cupping Coffee.

Download: SCA Coffee Cupping Form

Such systems bring objectivity to the quality evaluation process and enable ‘unispeak’ across functions/stakeholders – I hasten to add that the assessors must be professional and experienced tea tasters. The measurement system, therefore, is a tool to enhance the tasters’ skill expression and is not in lieu of the same.

Tea consumers want their tea to look leafy (as in Orthodox) but with the liquor strength of CTC – apparent contradictions. I have patented, and batch tested, a methodology for maximizing whole leaf grades and for achieving orthodox/CTC convergence.”

– Narendranath Dharmaraj

Consumer Feedback for Bulk Tea

A Unilever consumer survey concluded that most tea consumers worldwide prefer their tea to look ‘ leafy ‘ like orthodox, with the liquor tasting like CTC teas – strong, coloury. For the puritan tea man, this is blasphemy and an unholy combination. Such a consumer preference is particularly valid in the West Asia North Africa (WANA) region.

Even after I stopped working for Unilever, the thought of combining a seemingly contradictory set of tea characters excited me. Theoretically blending orthodox teas with CTC could achieve this but the resultant grade would be grossly uneven posing major bottlenecks in packaging of any form .

The persistence in this thought that the ‘Consumer knows best’ led me to do several trial and error methods to get to a tea that could be an orthodox/ CTC hybrid.

And finally, I arrived at something along the following lines, after much trial and error – Caveat, I have a provisional process patent for this!

Extruded Tea

The idea was to start with a CTC type of maceration to get the liquor color, strength, and infusibility and then try to get the leaf-shaped like orthodox grades. The lignin content in the tea leaf manifests in the form of fiber and is a tough nut to crack while attempting to bring about malleability in the leaf substrate with the further object of shaping it suitably. The first part required repeated machining while ensuring minimal temperature build-up (and consequent) loss of liquor quality and systematic removal of exposed fiber. Once we achieved a malleable mass, the idea was to extrude this substrate through suitable machinery with perforated dies configured to simulate the shape and size of the orthodox grades.

The results were promising. The objective of combining orthodox leaf appearance and CTC cup quality was achieved. We did make small commercial quantity which was bought by some exporters who were using it to blend with regular orthodox grades. Price offered were attractive.

There was, however, a general resistance from the traditional tea industry because the grades looked too engineered – a paradox when an even make is normally a very preferred attribute in tea grades, May be this was too even as never seen before and therefore presented a mindset issue – that’s what 150 years of mind conditioning does, I suppose!

However ,as a further attempt at refinement, the thought process was to look at 3D printing to tweak the die configuration to simulate the natural (conventionally made) grade shape. In addition, a 3D printing approach can potentially customize grade sizes based on client requirements and price targets.

Customizing grades takes me to the interesting bench trials, which involved manipulating the sequencing, temperature range and time of drying to achieve rolling efficiency and the fusion of normal and green tea machinery to achieve a quantum jump in grade recovery of leaf grades like OP, OPA, etc., as well as nutty BPS. All of these grades are currently in good demand in the WANA region and whose scale of production in factories is meager due to poor recovery of these grades , unless when very fine leaf is harvested, which of course, derails the economics by depressing crop productivity.

Stepping Up Development

Tea manufacture, as indeed tea agronomy, are in crying need of a re look . More of the same will not help the industry’s fortunes, which are sagging for various reasons.

Let’s shirk off the baggage of a 150-year-old mindset and get set for some development work that will change the rules of the game. Heritage is valuable. A stubborn mindset built over time diminishes value!

(c) copyright of the author. All rights reserved

Narendranath Dharmaraj is an independent strategic and operations consultant in tea and agribusiness, a TeaVision trustee and advisor to THIRST, an international roundtable for sustainable tea. Dharmaraj also advises Supriya Sahu at Indcoserve in Tamil Nadu and is a mentor and advisor to Sandip Thapa at CuppaTrade, a tea trading platform. A former president of UPASI, he served on the Tea Board of India. He worked 23 years managing tea plantations for Brooke Bond and Unilever, 11 years as head of tea at Harrisons Malayalam and eight years as chief executive managing Harrisons’ tea and rubber plantations.

Related

Tea Grower’s Cup of Woes by Narendranath Dharmaraj

Q|A Narendranath Dharmaraj by Aravinda Anantharaman

Word Press Blog: Musings by Narendranath Dharmaraj

Link to share this post with your colleagues

Signup and receive Tea Biz weekly in your inbox.