What you need to start the week.

- Future of Tea

- Tea Mechanization

The future is not an inheritance; it is an opportunity and an obligation. – Bill Clinton

SOUTHAMPTON, Bermuda – While the setting was idyllic, confronting the obstacles that lie ahead for the tea industry is the hard work undertaken last week by delegates at the 4th Annual North American Tea Conference.

A breakfast session called to focus on these broad issues raised more questions than answered. Additional suggestions and debate will benefit all.

To organize this process Tea Biz is working with John Snell of the Tea Association of Canada and Tea Association of the USA to pose each question on LinkedIn with an invitation for the global tea industry to comment and share their ideas. The questions are posted to Tea Biz for convenience; readers are encouraged to spread the discussion to related LinkedIn Groups including Tea Enthusiasts and Entrepreneurs, Tea Professionals, Tea Sommelier, Tea Importers and Exporters, World Tea News and Global Tea Elites.

The first conference question: “If rising costs in origin countries continues to erode margins, how will producers address this without harming returns to their workers, green leaf smallholders and shareholders?”

Additional questions will be posted through the week along with background briefings like the following:

Tea Mechanization

ILAM, Nepal – A headline in the Republica: “Tea Estates Reel Under Labor Shortage” succinctly makes the case for mechanization.

The article that followed noted a 58 percent drop in laborers working in tea since 2000. The shortage of laborers has affected production and processing at seven estates that “export tea worth millions of rupees” while paying NRs 158 ($1.57 per day) to a workforce demanding a raise to $2.

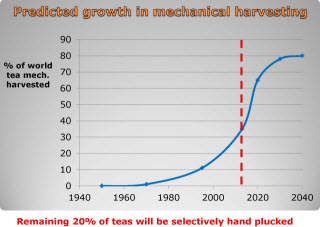

Nigel Melican, founder of Tea Craft, presented a rational and detailed argument for mechanization. He predicted 80 percent of the world’s tea will be mechanically harvested by 2040. Currently 35 percent is harvested by machine, a number that will quickly rise to 65 percent by 2020.

Today tea is rarely plucked two leaves and a bud, Melican told tea industry delegates attending the 4th Annual North American Tea Conference. The economics are clear, green leaf harvested by machine, including labor, fuel and depreciation is under 10 cents per kilo. Hand plucking costs three times more, said Melican. However, the deciding factor is “labor scarcity which is becoming a limiting factor which often compromises quality.”

Leaf quality is as good, often better than hand plucked, as demonstrated by prices paid at auction where mechanically plucked teas bring the same price as hand plucked, he said.

What’s driving mechanical harvesting?

Reasons vary from socio-economic concerns including parental aspirations for their children and urban drift to simple economics. Escalating wages are speeding adoption. Mechanical harvesting offers a longer harvesting opportunity for growers and better productivity per man, Melican told delegates.

A worker plucking tea by hand can harvest at most 60 pounds of green leaf per day. A ride-on harvester on tracks can pluck 10,000 pounds a day, he said.

Consumers remain “unsure” of the quality of machine picked tea, a point reinforced by marketers who claim the best teas are hand plucked, “thus ‘hand-picked’ tea becomes a shrewd selling point,” said Melican.

Has tea quality suffered due to mechanization?

“Informed opinion says, No,” he told delegates.

Melican predicted the rapid introduction of mechanized harvesting will accelerate and the “tea industry will polarize into two camps addressing very different markets.”

Melican predicted the rapid introduction of mechanized harvesting will accelerate and the “tea industry will polarize into two camps addressing very different markets.”

The first is industrial tea where the need to reduce the cost of production by increasing volume will lead to widespread adoption of mechanization.

“The other camp is specialty tea where hand-plucked is seen as value addition for quality,” said Melican. He warned this “will come at a high price” and suggested growers in many parts of the world may opt for handpicking early in the season when the teas command a premium and machine harvest in the summer and fall when quantity is the priority.

Conference question three: The increase in mechanization within the tea industry is relevant and unavoidable, but have we thought out the socio-economic issues involved?

Workers are migrating away from tea but there are still many who are not able to move and/or don’t want to. When you introduce a machine that does the work of 50 people, what is the structure to ensure that they continue to reap appropriate benefit from this transition?